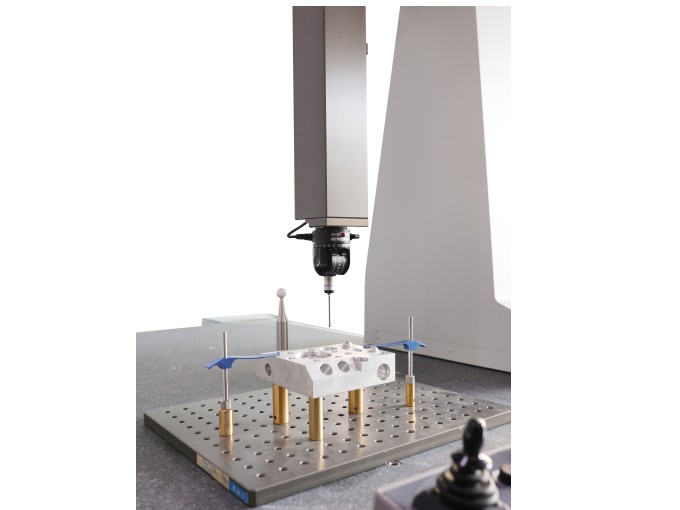

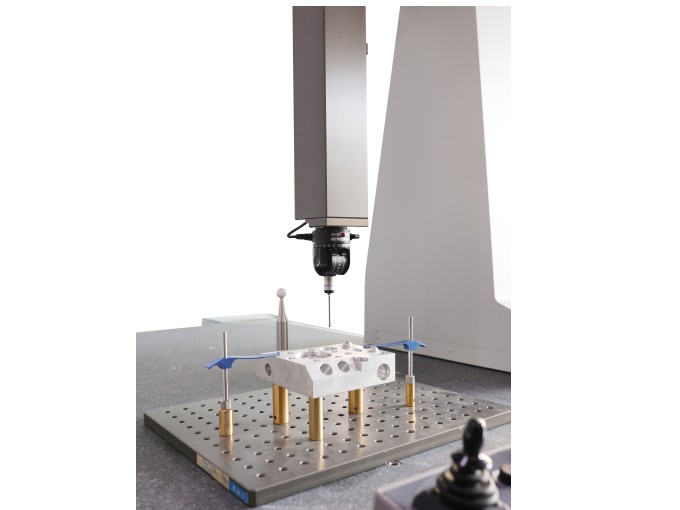

Natural Granite

00-grade natural granite base, column and worktable make it strong rigidity and small deformation to ensure stable accuracy.

Measuring Strokes(mm) |

Overall Dimension (mm) |

Machine Weight | Max. Part Weight |

||||

| X | Y | Z | Lx | Ly | Lz | ||

| 700 | 1000 | 600 | 1250 | 1935 | 2729 | 1600kg | 1800kg |

| Accuracy is according to GB/T 16857.2-2006(ISO 10360-2:2001) | |||||||

| Maximum permissible error of indication of a CMM for size measurement (mm) | Maximum permissible Probing Error (mm) | ||||||

| 2.8 + 3L/1000 | 2.8 | ||||||

| Dynamic Performance | |||||||

| 3D positioning speed(mm/s) | 3D acceleration (mm/s2) | ||||||

| 520 | 1386 | ||||||

| Room Required Specifications | |

| Room Temperature | 18~22°C |

| Temperature Gradient (in time) | 1°C /h |

| Temperature Gradient (in time) | 2°C /24h |

| Temperature Gradient (in the volume) | 1°C /m |

| Humidity Required Specifications | |

| Relative humidity | 25-75% |

| Air Supply System Required Specifications | |

| Min. air pressure | 5 bar [0.5 MPa] |

| Air consumption | 150 NL/min |

| Electrical requirements | |

| Voltage | 220 V ± 10% |

| Frequency | 50/60 Hz |

| Current | 15 A |

| A good earth ground (less than 4 W) is required for reliable operation of the electrical controls. | |